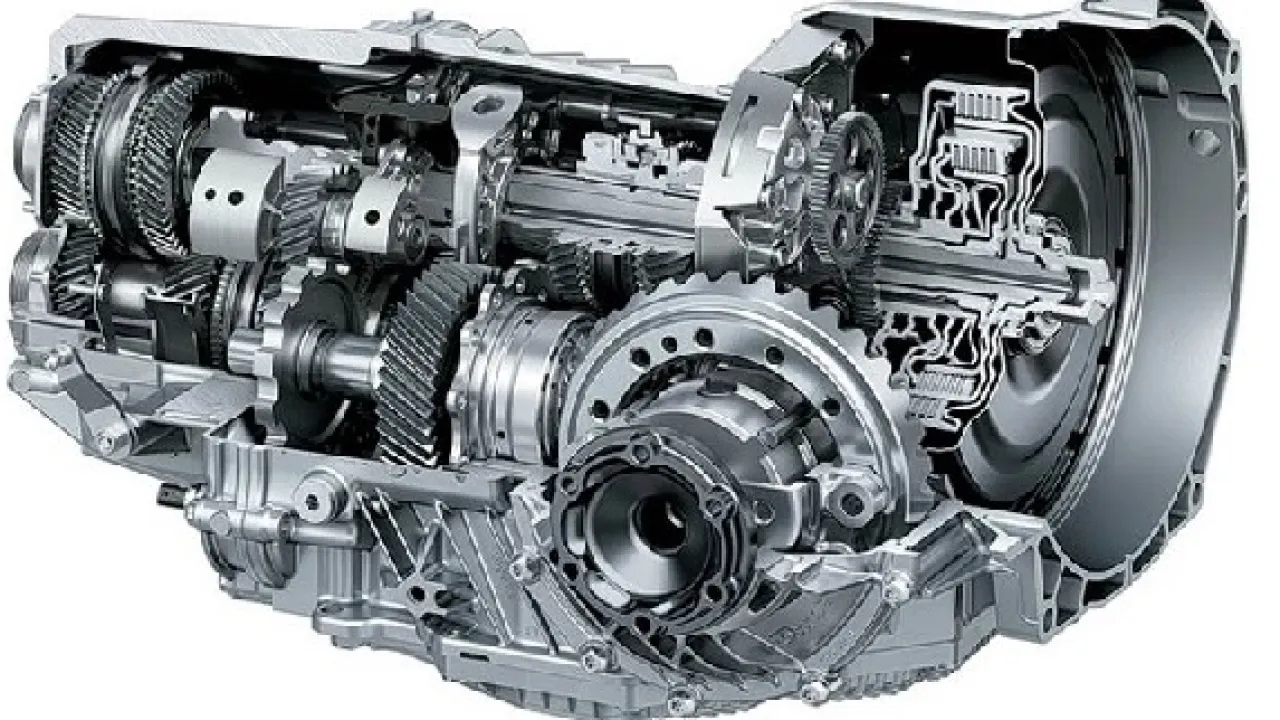

Your car’s gearbox is a complex and important mechanical piece of machinery.

It plays a crucial role in transferring power from the engine to the wheels

However, like any mechanical component, gearboxes require proper care and maintenance to ensure their longevity and optimal performance.

In this blog post, we will explore essential tips and maintenance practices to help you make your gearbox last longer.

1. Regular Service:

Regular inspections are vital for identifying potential issues before they escalate into major problems.

Look for signs of wear, such as unusual noises, leaks, or difficulty in shifting gears.

Pay attention to vibrations or abnormal temperature increases as they could indicate misalignment or inadequate lubrication.

Schedule routine inspections as recommended by the manufacturer or a qualified technician.

2. Lubrication:

Proper lubrication is crucial for the smooth operation of a gearbox.

Refer to the manufacturer’s guidelines to determine the appropriate lubricant type, viscosity, and change intervals.

Insufficient or contaminated lubrication can lead to increased friction, wear, and premature failure.

Monitor the oil levels regularly and ensure that the lubricant is clean and free from debris.

Most car manufacturers recommend changing the transmission fluid every 30,000 to 60,000 miles.

Replace the lubricant at recommended intervals or whenever contamination is suspected.

3. Use High-Quality Lubricants:

Using high-quality lubricants specifically designed for gearboxes can significantly enhance their lifespan.

These lubricants are formulated to withstand the high pressures and temperatures generated within the gearbox.

Consult the manufacturer’s recommendations or seek expert advice to ensure you select the right lubricant that meets the gearbox’s specifications and operating conditions.

4. Proper Gear Shifting Techniques:

Adopting correct gear shifting techniques can reduce stress on the gearbox.

Avoid abrupt and forceful gear changes, especially when the vehicle or machinery is under heavy load.

Allow the clutch to engage fully before applying throttle when shifting gears.

Additionally, refrain from using the gearbox as a braking mechanism by downshifting abruptly, as it can lead to excessive wear on the gear teeth.

5. Avoid Overloading:

Gearboxes are designed to handle specific loads.

Exceeding the recommended load limits can put excessive strain on the gears, bearings, and other components, leading to premature failure.

Ensure that you understand and adhere to the gearbox’s load capacity as specified by the manufacturer.

If you anticipate heavy loads, consider upgrading to a gearbox with higher torque or seek expert advice to determine the appropriate solution.

6. Maintain Proper Alignment:

Misalignment between the gearbox and the driven equipment can cause uneven stress distribution and accelerated wear.

Check and ensure that the gearbox is properly aligned with the input and output shafts.

If misalignment is detected, consult a professional to correct it promptly.

Proper alignment minimizes unnecessary wear, reduces vibrations, and prolongs the gearbox’s life.

7. Temperature Monitoring

Excessive heat can damage the gearbox components and degrade lubricants.

Install temperature sensors or gauges to monitor the gearbox’s operating temperature.

Ensure that the gearbox is adequately cooled to prevent overheating.

If temperatures exceed the manufacturer’s recommendations, investigate and rectify the underlying causes promptly.

Conclusion

Proper care and maintenance are crucial for ensuring the longevity and optimal performance of gearboxes.

By implementing the tips mentioned above and following the manufacturer’s guidelines, you can minimize wear, reduce the risk of failure, and extend the lifespan of your gearbox.

Remember that regular inspections, correct lubrication, proper gear-shifting techniques, load management, alignment maintenance, temperature monitoring, and expert assistance are essential factors in maximizing the lifespan of your gearbox.